MENU

Eichi Ⅱ in detail

Eichi Ⅱ, a masterpiece from a remarkable studio

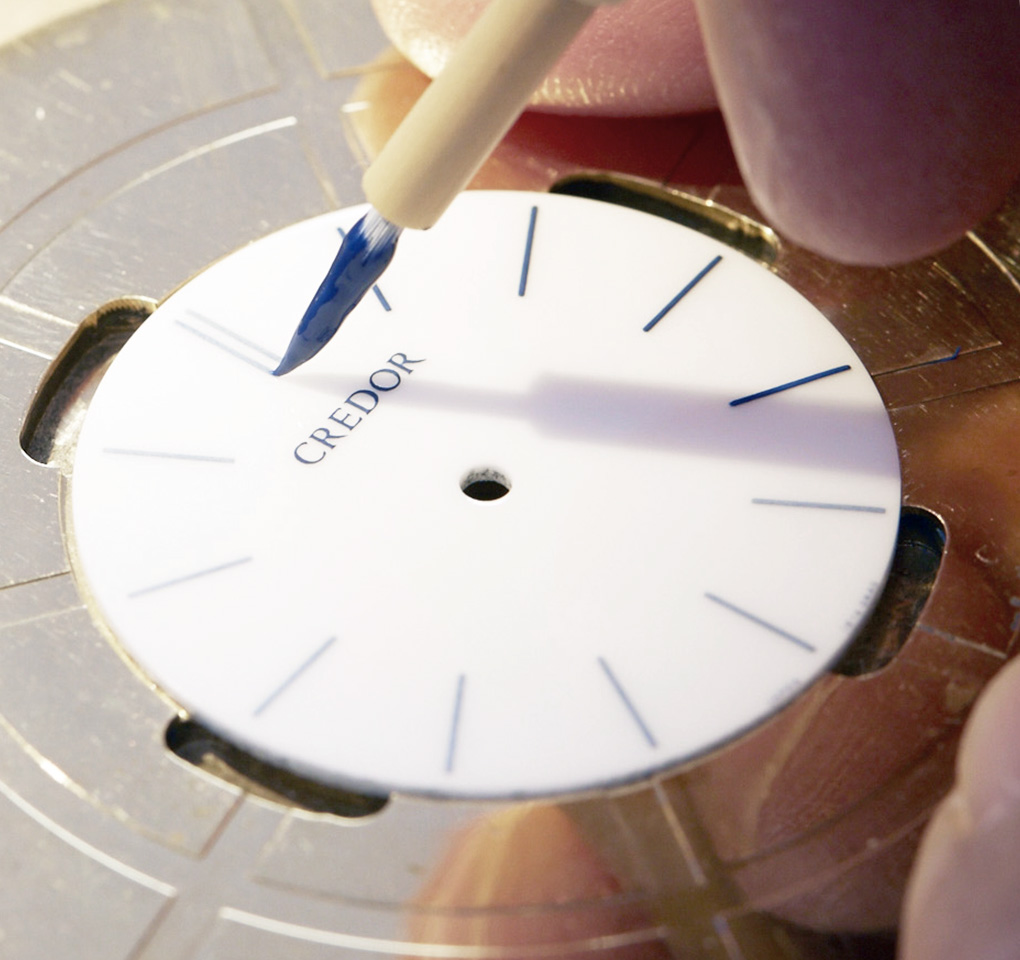

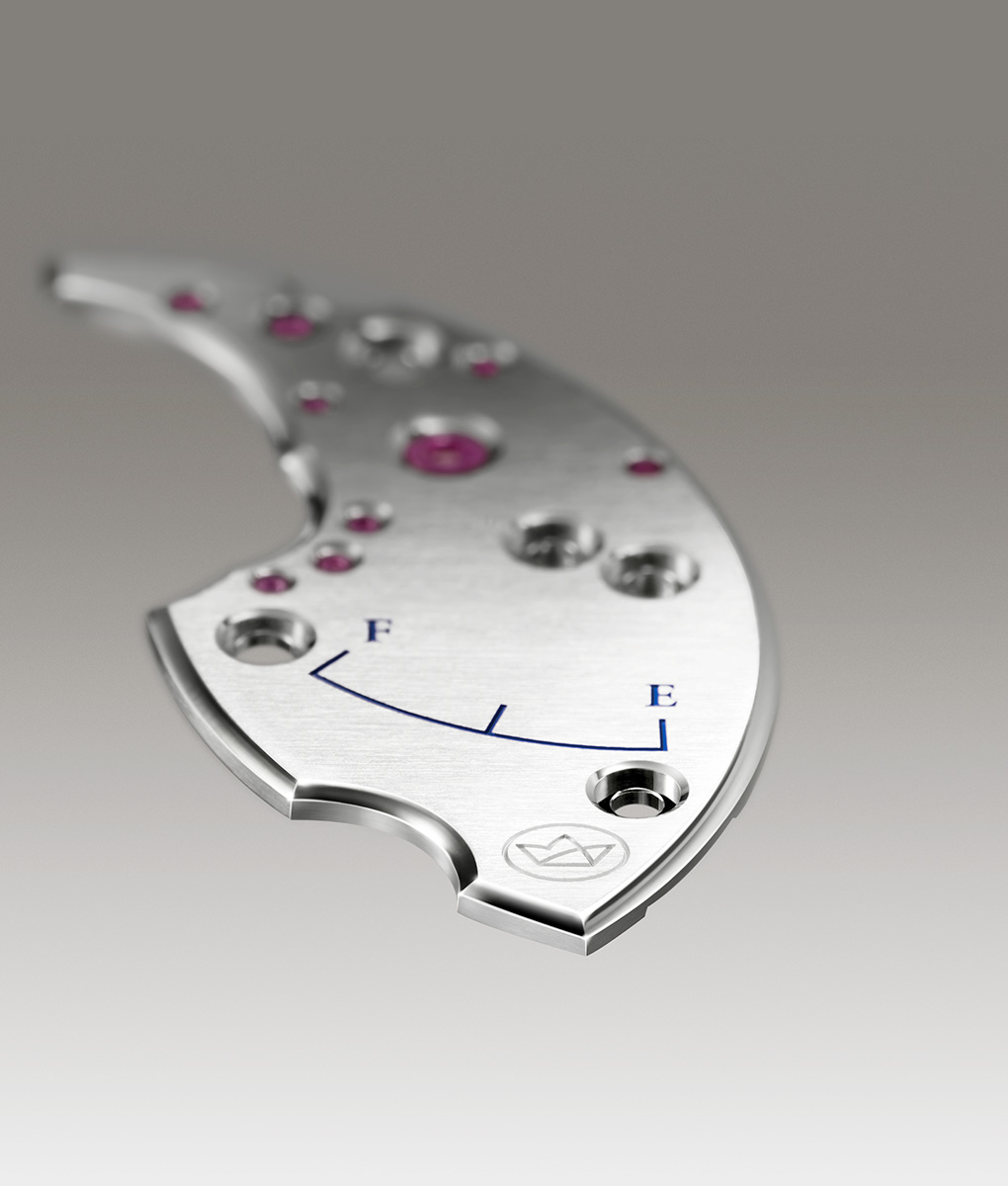

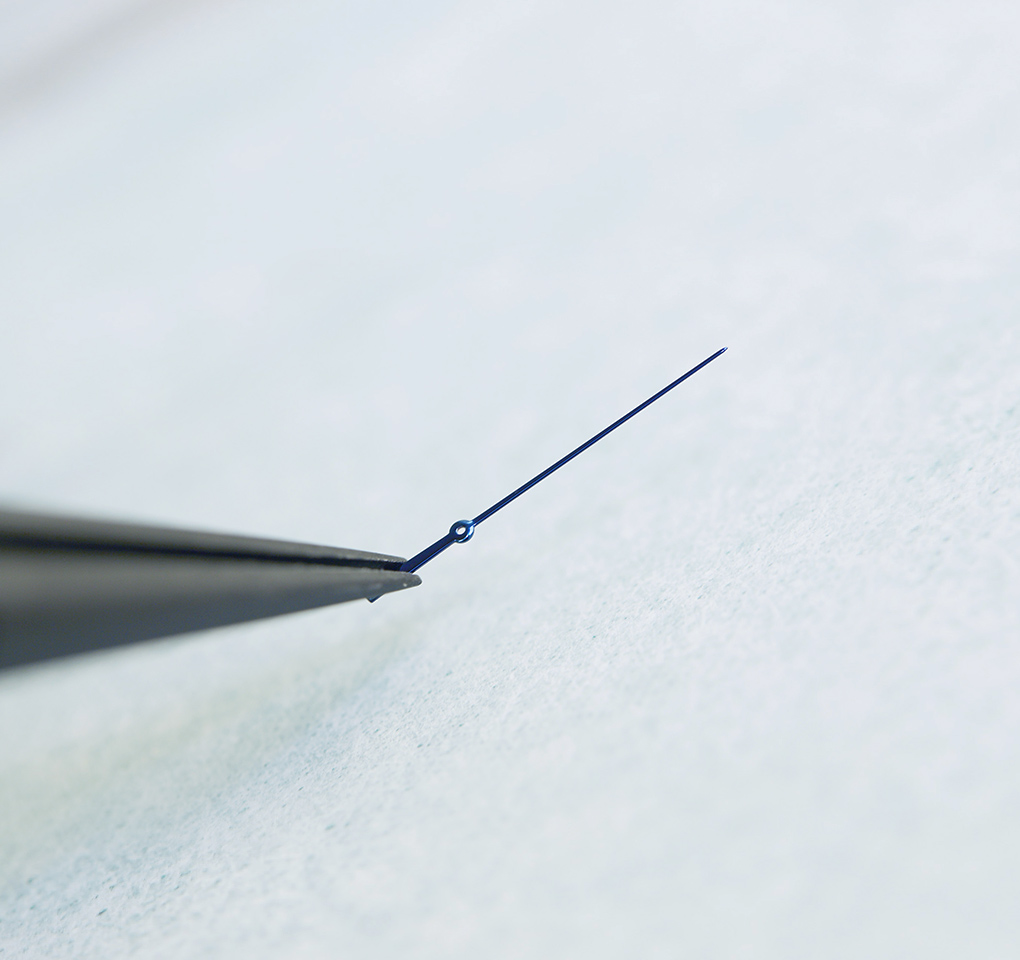

Eichi means wisdom in Japanese. The name reflects the fusion of traditional Japanese watchmaking skills with the highest and most advanced Spring Drive technology. From the design of every component to the hand painting of the dial, Eichi Ⅱ is the work of the elite team of watchmakers at the Micro Artist Studio in Seiko’s facility in Shiojiri in the Nagano prefecture of central Japan. Founded in 2000, this studio created the Spring Drive Sonnerie in 2006, the Spring Drive Minute Repeater in 2011 and the Grand Seiko Spring Drive 8 Day Power Reserve in 2016 as well as Eichi Ⅰ in 2008 and Eichi Ⅱ in 2014.